- High product quality due to constantly even contact of the knife with the die plate

- Length of the pellets produced can be influenced easily by the number of knives and by the speed of the knife rotor

- Quick release connections

- Easy access for cleaning the screws, mounting the die plate and quick change over of the die plate

- Safety device ensures that the pelletizer hood does not open until the motor is at a standstill

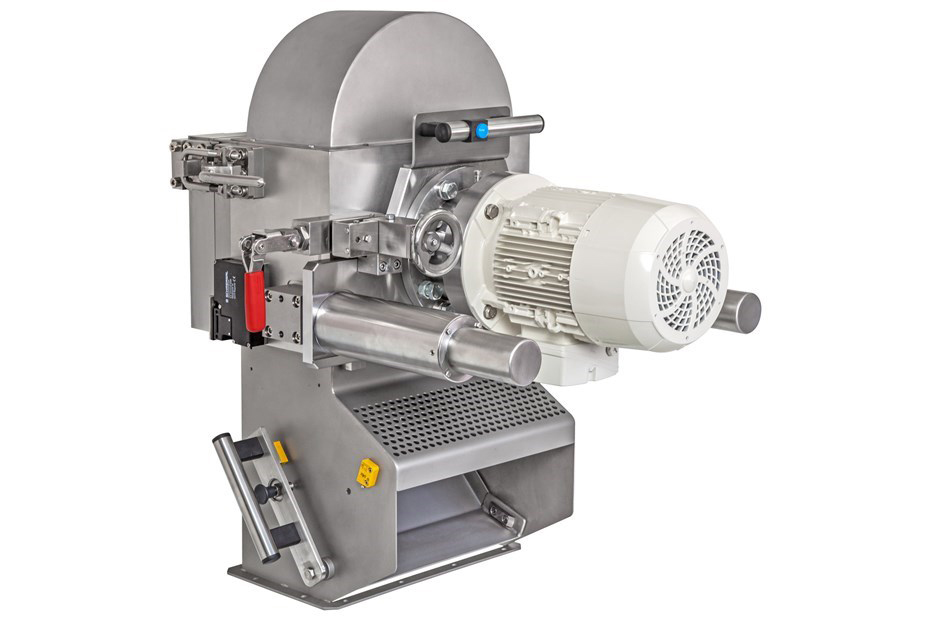

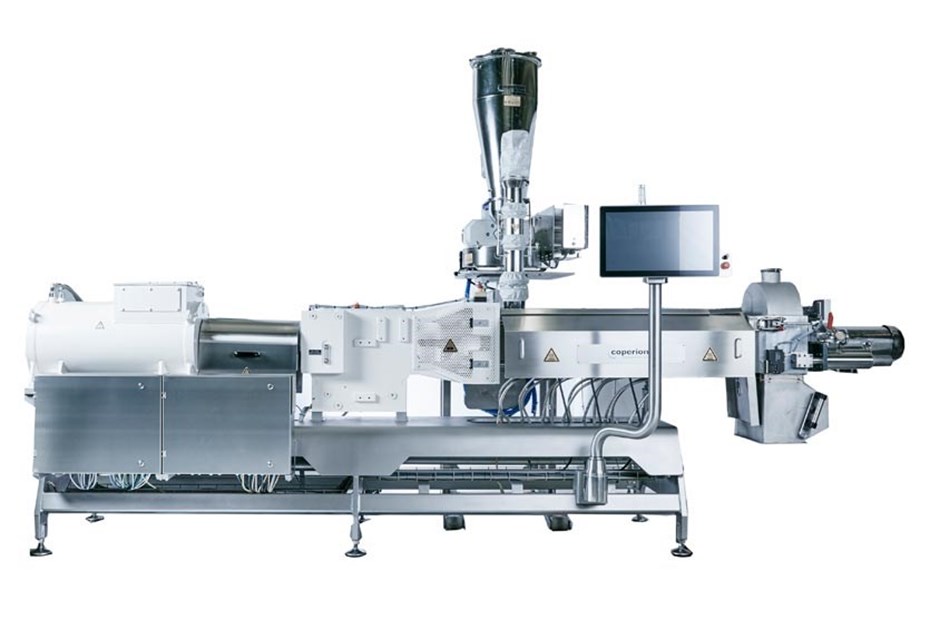

Centric Pelletizers ZGF

For directly expanded food stuffs, extruded chemical products and pharma applications

The ZGF centric pelletizer from Coperion has been used successfully for many years in extrusion plants for the production of directly expanded food stuffs such as cereals, aquatic feed or petfood. It is also used for the production of extruded products in the chemical industry and for pharmaceutical applications.

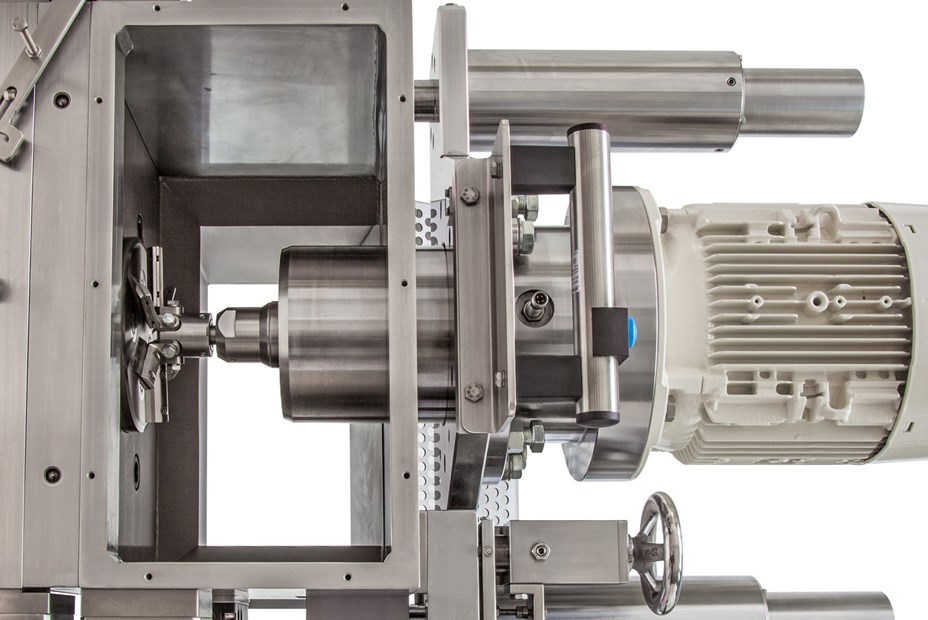

The knife rotor of the ZGF centric pelletizer is arranged centrally to the die plate. The product which emerges from the die plate in endless strands is cut off by the knife directly at the end of the extruder (hot die / head pelletizer). The length of the pellets produced can be influenced easily by the number of knives and by the speed of the knife rotor.

The pelletizer hood and the die holder in the ZGF centric pelletizer are swivellable and enable easy access for cleaning the screws, mounting the die plate and quick change over of the die plate. It is connected to the ZSK twin screw extruder by quick release connections.

The knife rotor is spring loaded on the die plate. This ensures a constantly even contact of the knife with the die plate. The distance between the knife blade and the die plate can be finely adjusted during operation. The start-up product in strand or pellet form is discharged through the start-up flap. A safety device ensures that the pelletizer hood does not open until the motor is at a standstill.

Inqueries