- Tablet press lubrication using Coperion K-Tron feeders (both volumetric and gravimetric) ensures uniform coating of the tablet press tools

- Coperion K-Tron’s superior weighing accuracy utilizing the patented SFT digital weighing technology provides accurate delivery of the lubricant or coating

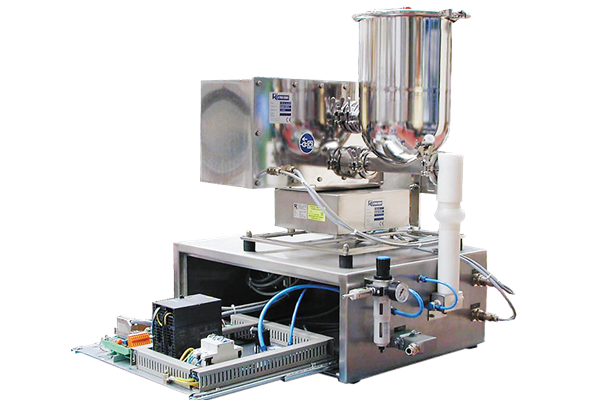

- The Coperion K-Tron Pharma feeder is designed specifically for ease of cleaning and engineered in accordance with the strictest cGMP design standards

- Coperion K-Tron can provide controls for complete integration with either the tablet press or the coater

- Tablet press lubrication and coating applications available as low as 50 g/h!

- Use of the Coperion K-Tron tablet press lubrication system can decrease overall lubricant consumption as well as increase tablet quality by decreasing the amount of lubricant which needs to be added to the blend

Tablet Coating and Press Lubrication

Coperion K-Tron Feeders are used in high accuracy dispersion for both tablet press lubrication and addition of powders to the coating process

Tablet press lubrication and powder dispersing for tablet coating are both processes which can be significantly enhanced using Coperion K-Tron pharmaceutical feeders. Recent co-operation of Coperion K-Tron with a number of tablet press manufacturers led to the development of feeders which feed a variety of lubricant powders direct to the press tooling by means of a gas injector. The gas in the pneumatic conveying line conveys the lubricant to a nozzle which uniformly coats all surfaces of the tablet press tools that are in contact with the granulate. Alternatively, Coperion K-Tron screw feeders are also used in conjunction with tablet coating machines, both batch and continuous, to meter the powdered materials direct to the coating machine. Finally, the Coperion K-Tron line of vibratory feeders are specifically designed to accurately deliver the uncoated tablets direct to the coating machine. All three operations described provide more efficient handling of the tablets, lower risk of over lubricating the tablet granulation, less off-spec tablet production and even dispersion of the powdered material on the tablet surface. Typical products are: tablet lubricants (e.g. magnesium stearate, calcium stearate, stearic acid), coatings (e.g. carnauba wax), opaquant extenders (e.g. talc).

Inqueries