- Experienced systems engineers can provide complete systems designs, from receipt of the raw material to the packaging process

- Ability to handle even the most difficult pet food and feed materials through use of highly accurate Coperion K-Tron feeders

- Extremely versatile Coperion ZSK Mv PLUS twin screw extruders and specially designed pelletizers/dies can achieve even the most complex pet product profile

- High free screw volume of Coperion ZSK extruder design can provide higher capacities than equivalent size extruders, as well as high wear resistance

- Sanitary designs are available for the complete Coperion and Coperion K-Tron product line, making cleaning and product changeover efficient and safe.

Pet Food, Pet Treats & Fish Feed

Complete Extruded Pet Food, Fish Food or Pet Treat Systems Capability

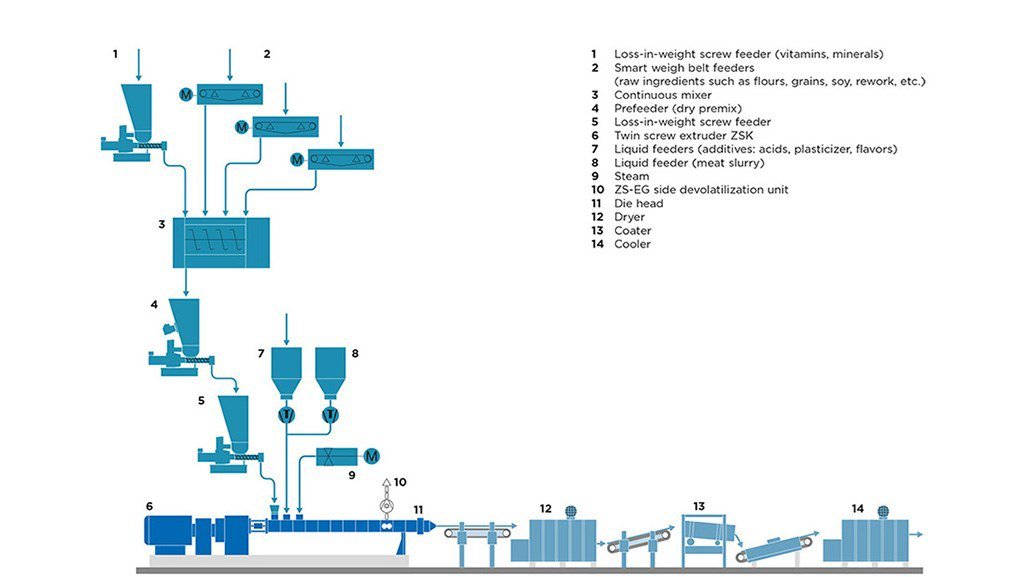

Whether manufacturing in a batch process or in higher volumes via continuous methods, Coperion and Coperion K-Tron feeders and material handling equipment as well as Coperion high efficiency extruders are used throughout the dry pet food and pet treat as well as aquatic fish feed manufacturing processes. Screw feeders (both volumetric and loss-in-weight), liquid loss-in-weight, and weigh belt feeders are used for metering and highly accurate feeding of ingredients into mixers (batch or continuous) and extruders as well as portioning end products for the packaging line. In addition, Coperion pneumatic conveying systems and components are used for the transfer of dry powder materials, such as grains, premixes, vitamins and even probiotics. Finally, the use of the Coperion ZSK Mv PLUS twin screw extruder delivers an extremely high product output and quality for optimal efficiency in dry pet food, fish food, and pet treat production. The ZGF centric pelletizer ensures highest product quality for direct expanded pet food, fish food or pet treats.

Typical products handled include grains, pet food kibble, pet treats, co-extruded pet treats, fish meal, protein, vitamins, pigments, meat and grain meals.

Inqueries