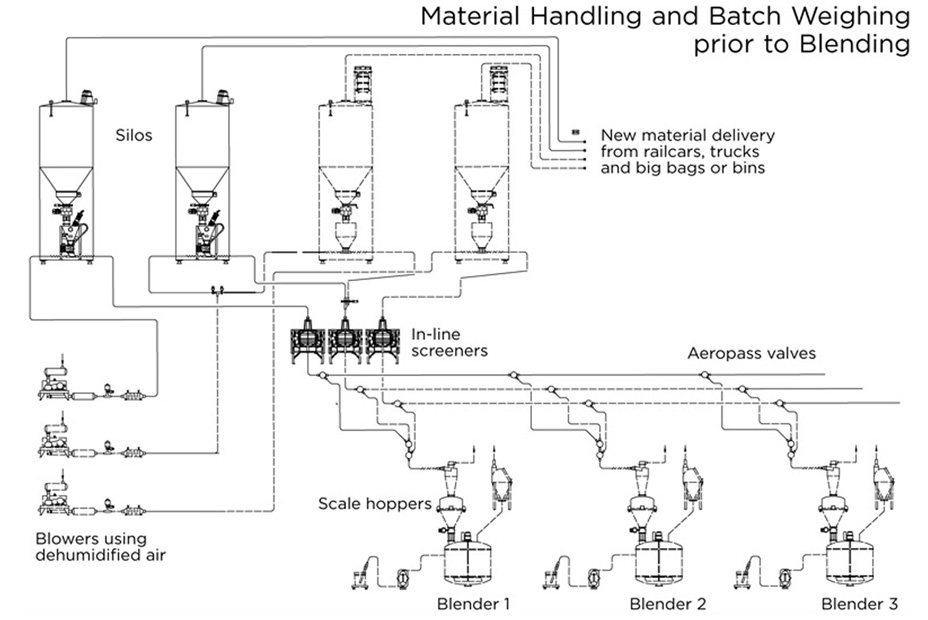

- Complete systems supply for flavor encapsulation from raw ingredient delivery, to weighing and batching of ingredients, mixing and extrusion, end-product feeding, and conveying

- Coperion extruders produce encapsulated flavors with a much smaller footprint than traditional spray dry methods

- Extrusion processes operate in a highly viscous state with very little to no water addition, so no subsequent drying is needed, resulting in a much lower overall process energy cost

- Sensitive flavors produced by Coperion extruders have considerably extended shelf life, especially citrus flavors

- Coperion K-Tron screw feeders offer high accuracy in weighing and batching expensive flavor ingredients and blends, thus saving on overall ingredient costs

- Coperion K-Tron and Coperion dense phase conveying systems allow for gentle transfer of the complete blend without segregation or degradation

- The versatile Coperion twin screw extrusion systems for flavor encapsulation are designed for quick recipe changes, thus making several flavor recipe profiles available with one machine

- Coperion and Coperion K-Tron’s extensive ingredient handling and flavor reaction expertise ensure the end user of ease in development of even the most difficult ingredient flavor profiles

Flavor Blends

Feeding, material handling and extrusion for flavor blends, encapsulated flavors and Maillard flavor reactions, aromas, vitamins, food additives

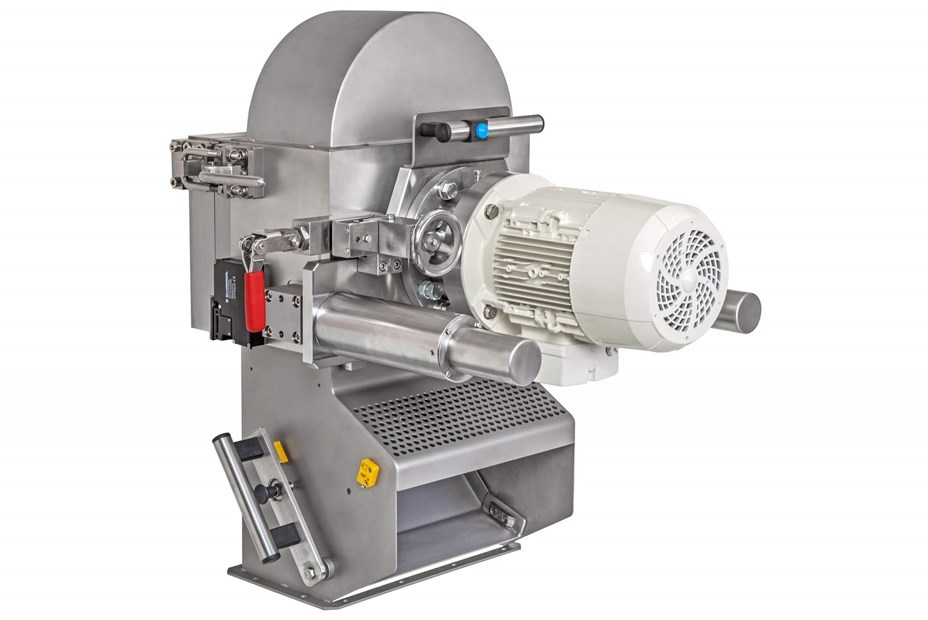

The use of flavors and aromas in food processing plays an important role in food consumption and consumer acceptance. Coperion K-Tron feeders and pneumatic conveying systems are used extensively in the food industry for the accurate and gentle handling of flavor blends to minimize aroma degradation. Coperion’s food components fulfill the highest demands in hygiene, easy cleaning and gentle product handling. In addition, Coperion high efficiency ZSK Mv PLUS twin screw extruders are used to encapsulate volatile flavors and aromas.

The encapsulated product can be used to create food products with improved shelf life, easy product handling and more controlled release properties. Encapsulated flavors are used in instant beverages, teas, confectionary and bakery product.

A second flavors application for the ZSK Mv PLUS extruder utilizes the Maillard reaction for flavor formation. The Maillard reaction is a chemical reaction between amino acids and reducing sugars which gives browned foods their desirable flavor. Savory flavors such as roasted onion, gravy base, roasted or cooked meat flavors can be created continuously in a very low moisture environment.

Typical products are: encapsulated flavors and blends (lemon, citrus, sugars, maltodextrins), miscellaneous flavor blends, Maillard flavors (toasting, roasting, baking, caramel).

Inqueries