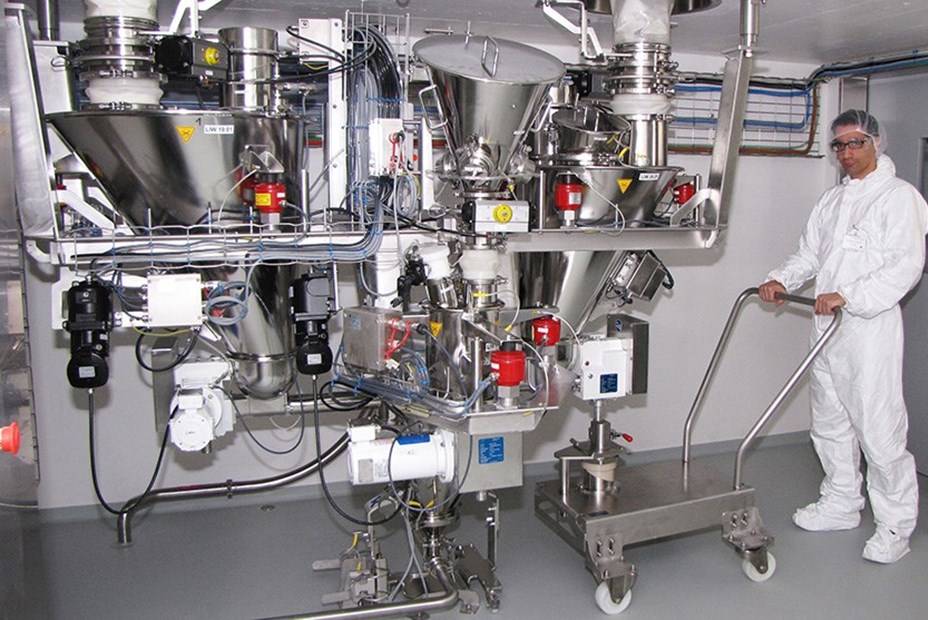

- Global systems engineering group with extensive application experience for the entire milk powder processing line ensures optimal design with an emphasis on product safety, quick product changeover and increased efficiency

- Highest sanitary design according to the current guidelines and regulations

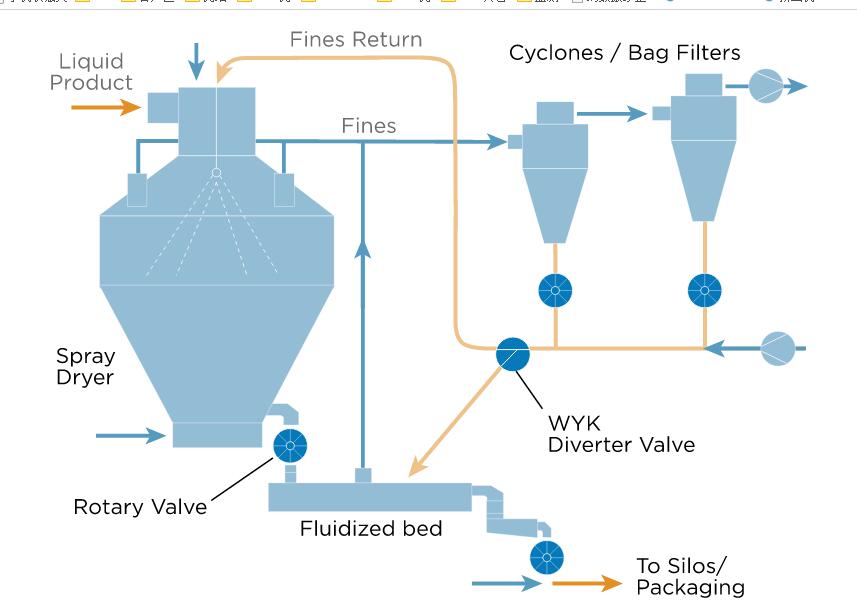

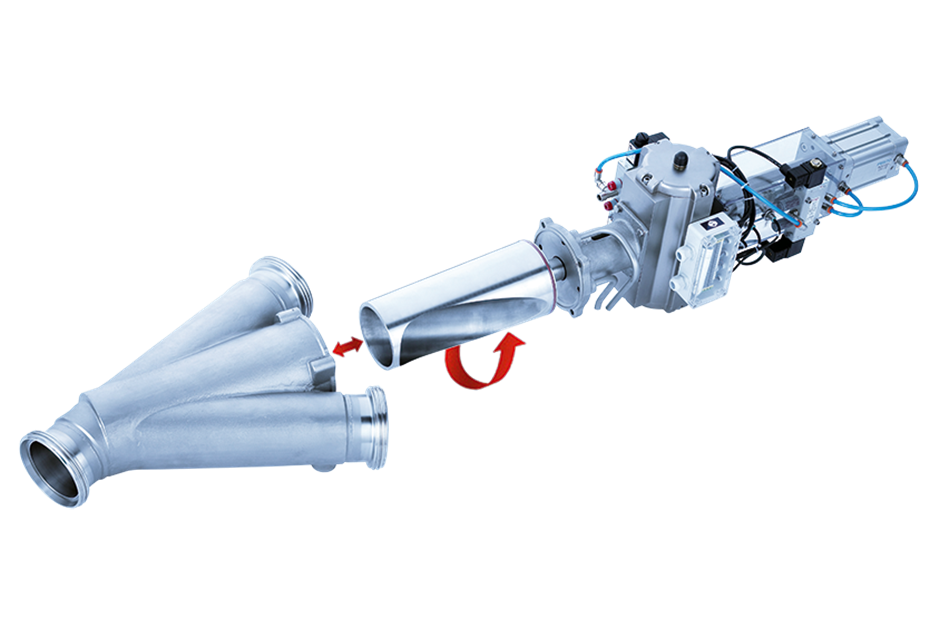

- Innovative, custom engineered Coperion rotary and diverter valves ensure reliable, long-term and safe operation

- Equipment and system designs in accordance with a wide variety of regulatory standards

- Coperion is an active member of the European Hygienic Engineering and Design Group (EHEDG) and therefore the latest developments and directives are directly incorporated into design of all components

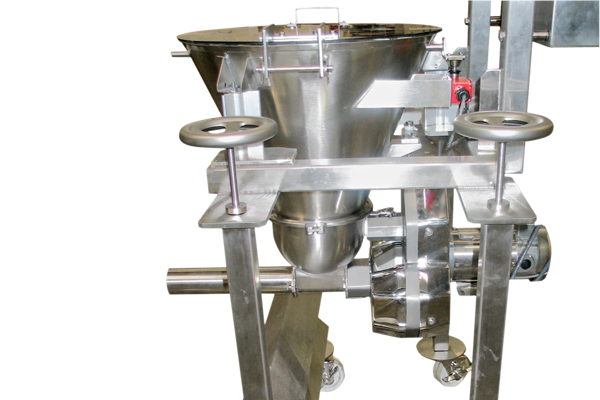

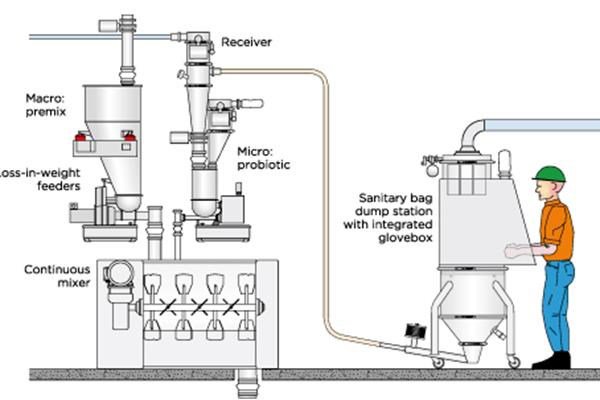

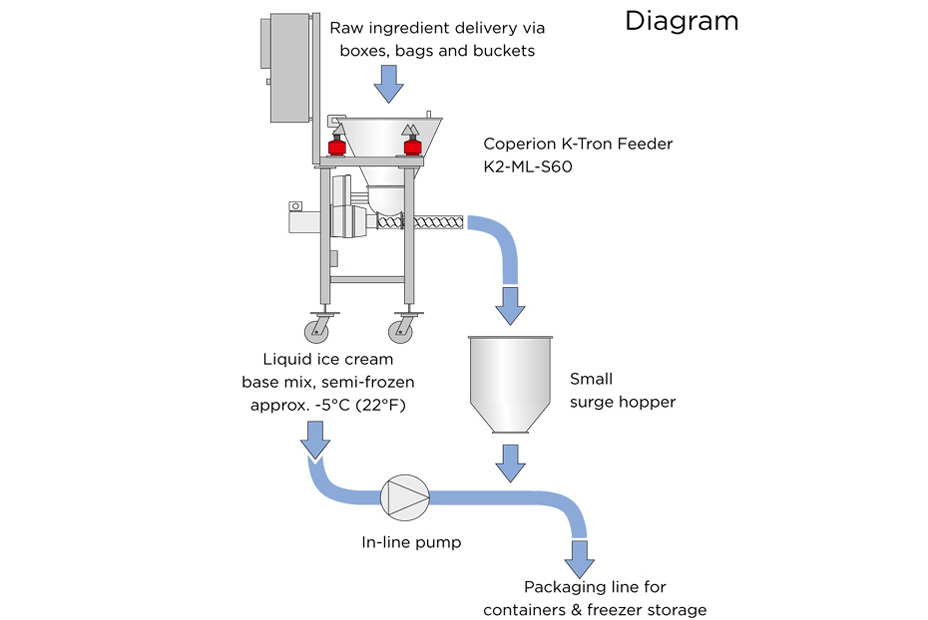

- Coperion K-Tron line of feeders provides maximum accuracy for adding high value ingredients like vitamins and probiotics

- Extensive material handling expertise for even the most difficult flowing dairy powders like lactose and maltodextrin

Dairy & Nutrition

Hygienic Design Feeders, Components and Conveying Systems for Sanitary

Applications

The production of dry dairy powders and infant/baby formulas requires extremely sanitary design of the equipment as well as high accuracy in the precise addition of ingredients to the formula blend. The system provided must also offer the versatility to handle a wide variety of difficult flowing and temperature-sensitive ingredients, including vitamins, nutrient additives and even probiotics. In addition, depending upon the type of process and the processing environment, the equipment must be able to be cleaned by either wet or dry cleaning methods. The hygienic designs provided by Coperion and Coperion K-Tron are easily adaptable for all of these requirements.

Products and ingredients may include: milk powder, whey powder, lactose, casein, cheese powder, infant formula, maltodextrine, probiotics, vitamins, baby food

Inqueries