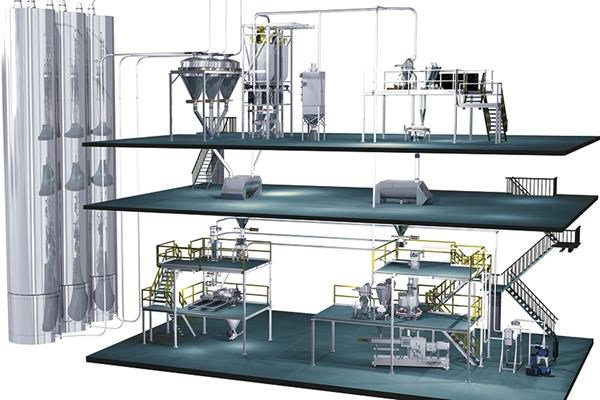

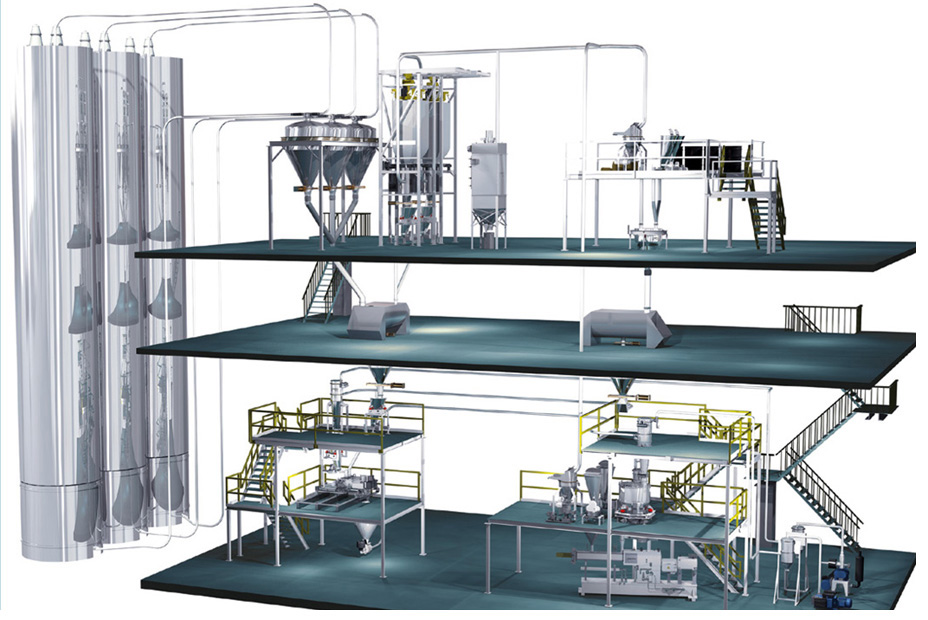

- Complete systems design integration of the cereal or snack food process for one source supply

- Global systems engineering with extensive application experience

- Coperion twin screw food extruders supply highest free screw volume to ensure maximum material loading and gentle product handling

- Innovative custom engineered Coperion rotary valves and diverter valves ensure reliable, long term operation

- Standard materials of construction on Coperion extruders provide optimal wear resistance on abrasive ingredients used in snack and cereal processing

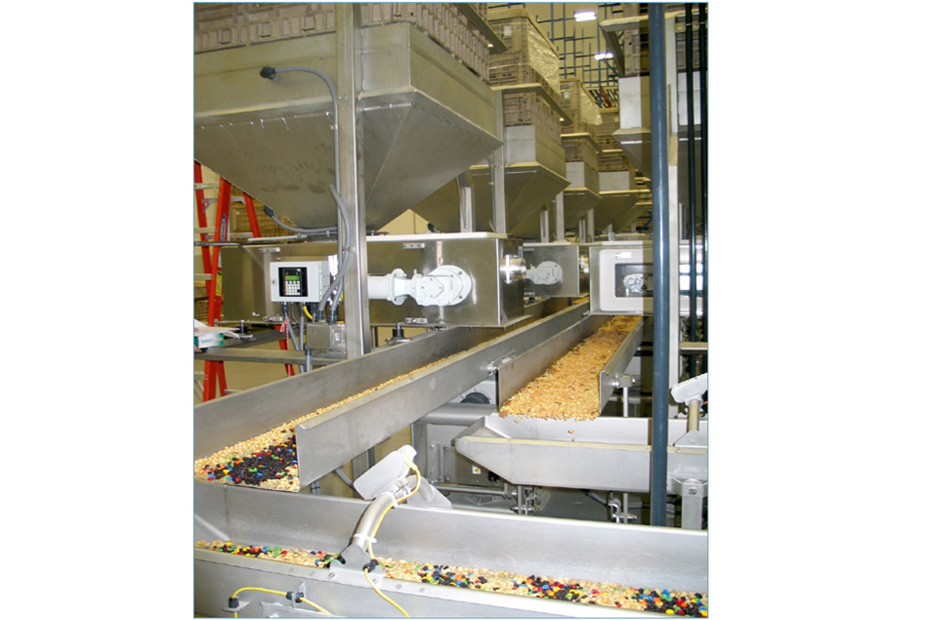

- Coperion K-Tron line of feeders and batch weighers provide the highest accuracy to ensure optimal control of ingredient costs

- Superior global service network to ensure 24-7 support and coverage of your complete cereal and snack food processing line

Cereals & Snack Foods

Accurate feeding, gentle material handling and highly efficient extrusion

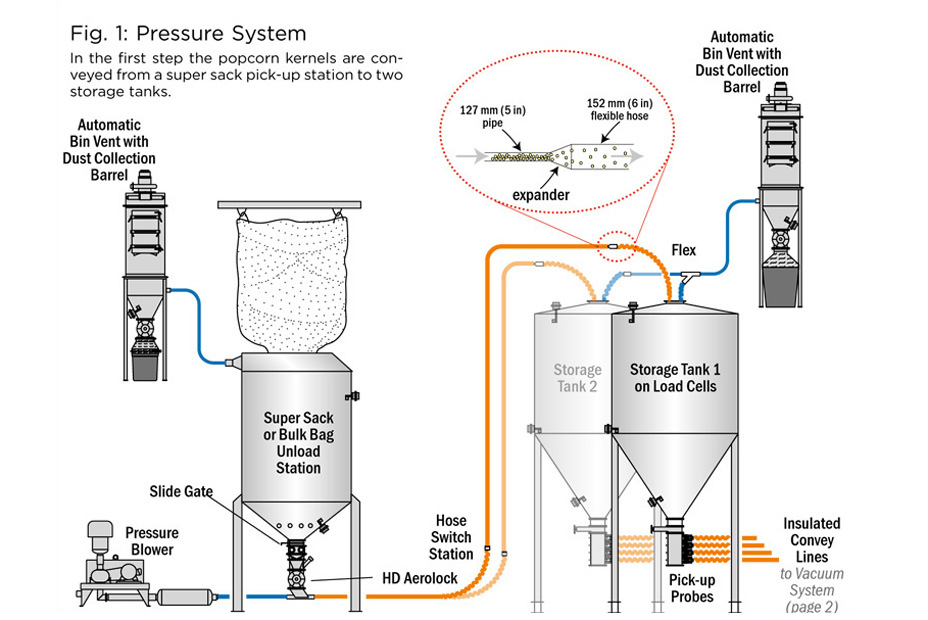

From material transfer of your ingredients, to automatization of your batch weighing process for majors, minors and micros, to extrusion of your snack food or cereals, the Coperion and Coperion K-Tron team can provide the optimal process solution. Coperion K-Tron highly accurate feeders and pneumatic conveying systems are used for the transfer, weighing and feeding to the mixer and/or extrusion steps. Coperion provides snack food and cereal ingredients components that fulfill the highest demands in hygiene, easy cleaning and gentle product handling. Coperion highly efficient, wear-resistant twin screw extruders are used for the production of various cereal and snack food types including cold formed pellets for flaked cereal, puffed cereals, as well as direct expanded and coextruded cereals and snacks.

Products and ingredients may include: flaked cereal, puffed cereals, puffed snacks, pillow snacks, muesli, trail mix or party mix, flatbreads, popcorn, salt and seasonings for coating snack foods, corn meal, grains (including corn, wheat , oats, rice and barley), various nuts, various flours.

Inqueries