| Essence material |

Norm Bezeichnung |

Hardness [HRC] |

Wear resistance |

Corrosion resistance |

Thermal material expansion (25 - 400 °C) [1/MK] |

Essential alloy elements [Gew.-%] | |||

| RT | 300°C | Cr | V | C | |||||

| R123.6 | X230CrVMoW18-6 | 64 | 54 | • • • • | • • | 11,7 | 18,0 | 6,0 | 2,3 |

| R123.3 | X270CrVMoW17-9 | 64 | 54 | • • • • • | • • | 12,1 | 17,0 | 9,0 | 2,7 |

| R123 | X220CrVMoW20-4 | 62 | 53 | • • • | • • | 11,4 | 20,0 | 4,0 | 2,2 |

| Delivery dimensions | Delivery form | |

| Screws: | Ø 14 mm - 70 mm | Screws: completely finished according to the customers drawing |

| PM-HIP steel rods: | Ø 25 mm - 70 mm Herstellungslängen bis zu 4000 mm |

PM-HIP steel rods |

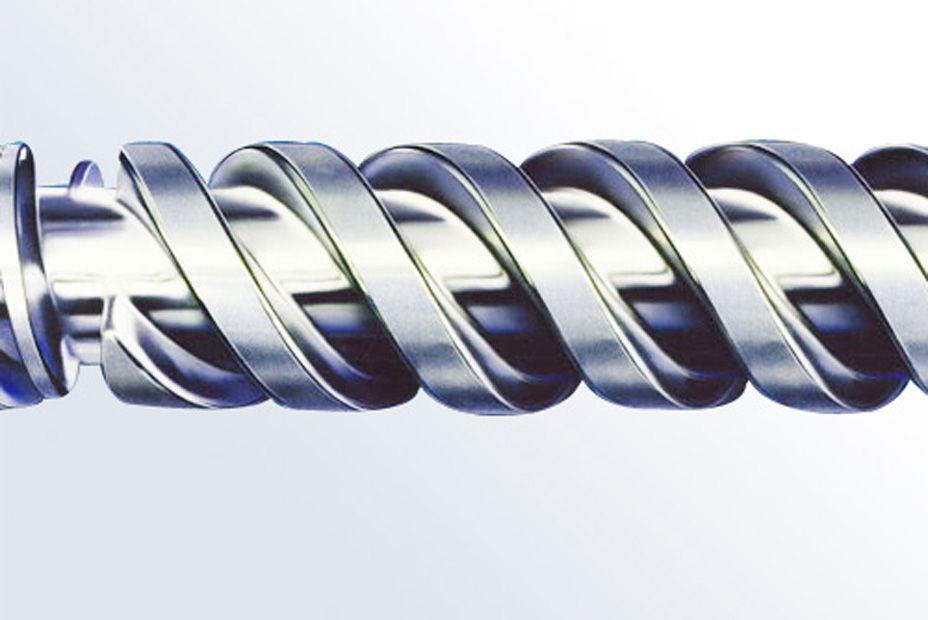

Technical specifications for hard-face flight screws

| FE-Basis | |||||||||

| Essence material |

Norm description |

Hardness [HRC] |

Wear resistance |

Corrosion resistance |

Thermal material expansion (25 - 400 °C) [1/MK] |

Essential alloy elements [Gew.-%] | |||

| RT | 300°C | Cr | V | C | |||||

| EC3 | X395VCrWMo16-13 | 56-59 | 54 | • • • • • | • • | 12,2 | 13 | 16 | 4,0 |

| CO-Basis | ||||||||||

| Essence material |

Norm description |

Hardness [HRC] |

Wear resistance |

Corrosion resistance |

Thermal material expansion (25 - 400 °C) [1/MK] |

Essential alloy elements [Gew.-%] | ||||

| RT |

300°C hardened |

Cr | W | Si | C | |||||

| ES6 | CoCr28W5 | 38-41 | 3 | • | • • • | 13,9 | 28 | 5 | 1,5 | 0,9 |

| ES12 | CoCr27W10 | 45-48 | 41 | • • | • • • | 12,9 | 27 | 10 | 1,5 | 2,0 |

| ES1 | CoCr33W13 | 52-56 | 48 | • • • | • • • | 12,1 | 33 | 13 | 1,2 | 2,5 |

| NI-Basis | |||||||||||||

| Essence material |

Norm description |

Hardness [HRC] |

Wear resistance |

Corrosion wider- stand |

Thermal material expansion (25 - 400 °C) [1/MK] |

Essential alloy elements [Gew.-%] |

|||||||

| RT | 300°C | Cr | Mo | W | Co | B | SI | C | |||||

| EP50 | NiCr17Mo16 | 48-52 | 49 | • • • | • • • • | 11,7 | 17 | 16 | 6 | 5 | 1 | 1,8 | 1,1 |

| EP50 Plus | NiW20Cr14Mo13 | 51-55 | 52 | • • • • | • • • • | 11,4 | 14 | 13 | 20 | 4 | 0,8 | 1,5 | 1,9 |

| material | material Nr. |

Yield strength Rp0,2 [MPa] |

Tensile strength Rm [MPa] |

Elongation to fraction A(I=5d) [%] |

Surface hardness after ion-nitriding HV5 bei RT |

Depth of nitrided zone [mm] |

| 31CrMoV9 | 1.8519 | 780 | 930 | 15 | 720 | 0,30 |

| X35CrMo17-1 | 1.4122 | 470 | 850 | 14 | 1100 | 0,15 |

| Inconel 625 | 2.4856 | 415 | 870 | 45 | - | - |

| Delivery dimensions | Delivery form |

| Ø 50 mm - 350 mm | Screw blanks with armouring, pre-ground +0,3 mm to nominal dimension |

| Length max. 9000 mm | Screws completely finished according to the customer’s drawing |