- Hygienic product design: open frame, stainless steel

- Easy to clean: less downtimes due to fast, efficient cleaning

- Less inspection due to optimal accessibility

- Control system: easy to operate, smart and safe

- High operational reliability and durability

- Specific torque 11.3 Nm/cm3

- Screw speed up to 1800 min-1

Food Extruders

The ideal extrusion system for many types of food and pet food

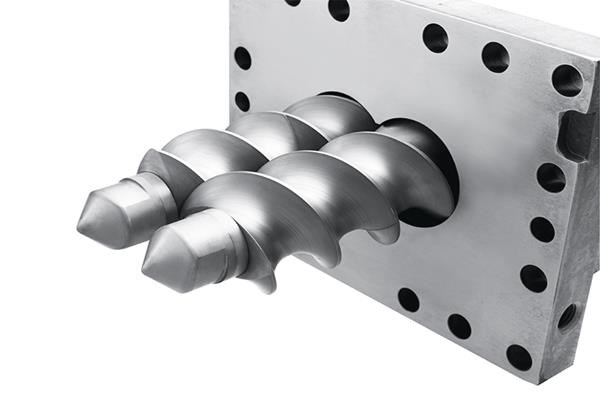

Coperion’s twin screw extruder ZSK Mv PLUS provides ideal conditions for the extrusion of many types of food and pet food products. The process section of the ZSK twin screw extruder consists of several barrels in which the co-rotating screws operate. The closely intermeshing screws with their tight selfwiping profile eliminate stagnant zones over the whole length of the process section. The effect of this is a constantly high conveying efficiency and perfect self-cleaning.

The modular design of the ZSK Mv PLUS and its unusual combination of free screw volume, screw speed and torque enable this twin screw extruder series to be individually configured for every application. The complete portfolio includes a wide range of sizes, allowing customers to process any required throughput range from laboratory to production scale.

Inqueries